ENERGY_PERFORMANCE_ASSESSMENT_FOR_EQUIPMENT_AND_UTILITY_SYSTEMS_(CHAPTER-13:ENERGY PERFORMANCE ASSESSMENT OF CEMENT INDUSTRY)

ENERGY PERFORMANCE ASSESSMENT FOR EQUIPMENT AND UTILITY SYSTEMS

(CHAPTER-13:ENERGY PERFORMANCE ASSESSMENT OF CEMENT INDUSTRY)

Introduction

Cement acts as a bonding agent, holding particles of aggregate together to form concrete. Cement production is highly energy intensive and involves the chemical combination of calcium carbonate (limestone), silica, alumina, iron ore, and small amounts of other materials. Cement is produced by burning limestone to make clinker, and the clinker is blended with additives and then finely ground to produce different cement types. Desired physical and chemical properties of cement can be obtained by changing the percentages of basic chemical components (CaO, AI,O,, Fe,O,, MgO, SiO,, etc.). Mostly the cement produced is of Portland cement. Other cement types include white, masonry, slag, aluminous, and regulated-set cement. Cement production involves quarrying and preparing the raw materials, producing clinker through pyroprocessing the materials in huge rotary kilns at high temperatures, and grinding the resulting product into fine powder.

Cement Manufacturing Process

The basic process of Cement production as shown in Figure 13.1 involves

¢ Acquisition of raw materials

¢ Preparation of the raw materials for pyroprocessing

¢ Pyroprocessing of the raw materials to form Portland cement clinker, and,

¢ Grinding the clinker to Portland Cement

Description of production processes

Mining: Limestone, the key raw material is mined in the quarries with compressed air drilling and subsequently blasting with explosives. The mined limestone is transported through dumpers or ropeways to the plant. Surface mining is gradually gaining ground because of its eco friendliness.

Crushing: The limestone as mined is fed to a primary and secondary crusher where the size is reduced to 25 mm. Of late even a tertiary crusher is used to further reduce the inlet size to the mill. The crushed limestone is stored in the stockpile through stacker conveyors. The crushed limestone, bauxite and ferrite are stored in feed hoppers from where they are fed to the raw mill via weigh feeders in the required proportion.

Raw Materials Preparation: For dry-process cement making, the raw materials need to be ground into a flowable powder before entering the kiln. Generally ball mills or vertical roller mills are used. Modern cement plants mostly use vertical roller mills. Roller mills for grinding raw materials and separators or classifiers for separating ground particles are the two key energy consuming pieces of equipment at this process stage. Along with grinding simultaneous drying of raw materials using hot gases from the preheater exhaust also takes place.

Coal Milling: In plants using coal, coal mills are part of the system to provide dried pulverized coal to kiln and precalciner. The raw coal from stock yard is crushed in a hammer crusher and fed to the coal mill. The coal mill can be an air swept ball mill or vertical roller mill where the coal particles are collected in the bag filter through a grit separator. The required size is 80 % on 90 micron and less than 2% on 212 micron. Hot air generated in a coal fired furnace or hot air from clinker cooler/preheater exhaust is used in the drying of coal in the mill.

Pyro processing: The function of the kiln in the cement industry is to first convert CaCO, into CaO and then react Silica, Aluminum Oxide, Ferric Oxide, and Calcium Oxide with the free lime to form clinker compounds: C3S, C2S, C3A, and C4AF. The raw material mix enters the kiln at the elevated end, and the combustion fuels generally are introduced into the lower end of the kiln in a ountercurrent manner. The materials are continuously and slowly moved to the lower end by rotation of the kiln.

Pulverized coal, gas, pet coke or Oil are the fuels generally used. This system transforms the raw mix into clinkers, which are gray, glass-hard, spherically shaped nodules that range from 0.32 to 5.1 centimeters (cm) in diameter. The chemical reactions and physical processes that constitute the transformation are quite complex, but they can be viewed conceptually as the following sequential events:

o Evaporation of uncombined water from raw materials as material temperature increases to 100 °C

o Dehydration as the material temperature increases from 100 °C to approximately 430 °C to form oxides of silicon, aluminum, and iron;

o Calcination, during which carbon dioxide (CO, ) is evolved, between 900 °C and 982 °C to form CaO

o Reaction of the oxides in the burning zone of the rotary kiln to form cement clinker at temperatures of approximately 1510 °C

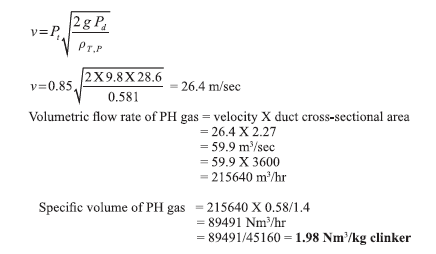

Pre heater and Pre calciner: Preheaters are cyclones which are arranged vertically, in series, and are supported by a structure known as the preheater tower. Hot exhaust gases from the rotary kiln pass counter currently through the downward-moving raw materials in the preheater vessels. Compared with the simple rotary kiln, the heat transfer rate is significantly increased, the degree of heat utilization is more complete, and the process time is markedly reduced owing to the intimate contact of the solid particles with the hot gases. The improved heat transfer allows the length of the rotary kiln to be reduced or in other words for the existing kiln if retrofitted, increases the production.

Additional thermal efficiencies and productivity gains have been achieved by diverting some fuel to a calciner vessel at the base of the preheater tower. This system is called the preheater/precalciner process. While a substantial amount of fuel is used in the precalciner, at least 40 percent of the thermal energy is required in the rotary kiln.

Upto 95 % of the rawmeal gets calcined before entering the kiln. Calciner systems sometimes use lower-quality fuels (e.g., less-volatile matter) as a means of improving process economics. From pre-heater and pre-calciner, 60 % of flue gases travel towards raw mill and 40 % to conditioning tower where water injection is used to condition the gases. These gases are ultimately passed through electrostatic precipitator (ESP) for the maximum removal of particulate matters.

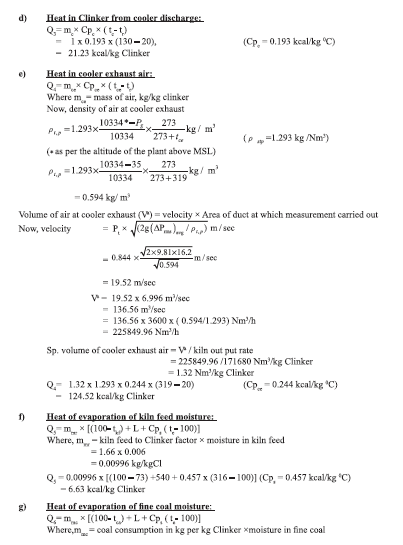

Clinker Cooler: The hot output from the kiln (clinker) is cooled from 1450 °C to 130 °C in the grate cooler with a series of fans. The cooler has two tasks: to recover as much heat as possible from hot clinker so as to return it to the process; and to reduce the clinker temperature to a level suitable for the equipment downstream. The hot air from recuperation zone is used for main burning air (secondary air) and precalciner fuel (tertiary air). The remaining air is sent to the stack through multiclones or ESP. Once clinker leaves the kiln it must be cooled rapidly to ensure the maximum yield for the compound that contributes to the hardening properties of cement. The main cooling technologies are the reciprocating grate cooler and the tube or planetary cooler.

Finish Milling: In this final process step, the cooled clinker is mixed with additives to make cement and ground using the mill technologies described earlier. The grinding process occurs in a closed system with an air separator that divides the cement particles according to size. Material that has not been completely ground is sent through the system again. Finish milling is the grinding of clinker to produce a fine grey powder. Gypsum (CaSO,) is blended with the ground clinker, along with other materials, to produce finished cement. Gypsum controls the rate of hydration of the cement in the cement-setting process. The cement thus produced is collected in the bagfilter and taken to cement silos through a vertical pneumatic pump. The energy used for cement grinding depends on the type of materials added to the clinker and on the desired fineness of the final product. Cement fineness 1s generally measured in a unit called Blaine, which has the dimensions of cm? /g and gives the total surface area of material per gram of cement. Higher Blaine indicates more finely ground cement, which requires more energy to produce. Portland cement commonly has a Blaine of 3000-3500 cm2 /g.

Energy flow

The cement making process is highly energy intensive accounting for nearly 40 — 50 % of the production costs. This provides ample opportunities for reducing energy consumption as many of the cement plants in developing countries consume much more than the best achieved figures in developed countries.

Electrical Energy:

The energy flows in a typical cement plant is given in the Figure 13.2 below. The major electrical energy consumption areas are mill drives, fans and conveying systems. About 30% of electric power is consumed for finish grinding, and below 30% is consumed by the clinker burning process. Raw mill circuit is another major consumer accounting for 24 % of the energy.The raw mill circuit and finish grinding process mainly consumes electric power for the mill, and the clinker burning process mainly for the fan.

Thermal Energy:

Thermal energy accounts for almost half the energy costs incurred in cement manufacture. A variety of fuels such as coal, pet coke, gas and oil in addition to unconventional fuels such as used tires, incinerable hazardous wastes, agro residues etc are used in the cement plant. The major use of thermal energy is in the kiln and precalciner. In plants using coal, an external coal or oil fired furnace is used for generation of hot air required for coal mills. The average thermal energy consumption kcal/kg of Clinker is given in the table 13.1.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

Comments